Menu

AL-2 / Aquaculture / Aquaculture RAS Tasmania

Case: Aquaculture RAS Tasmania

Huon Aquaculture in Tasmania produce Salmon, from egg to the final processed product. The growing demand for fish and protein in our diets required a larger Smolt unit. A new RAS hatchery was established on the River Huon which at the time of construction was the most advanced in the Southern Hemisphere. The company has big focus on sustainability and zero discharge.

Challenge

Proper treatment of effluent from the new facility was fundamental for assuring government approval of the project.

- Removal of sludge and feed waste

- Removal of organic material and phosphorous

- Dewatering of the removed slam fraction

Solution

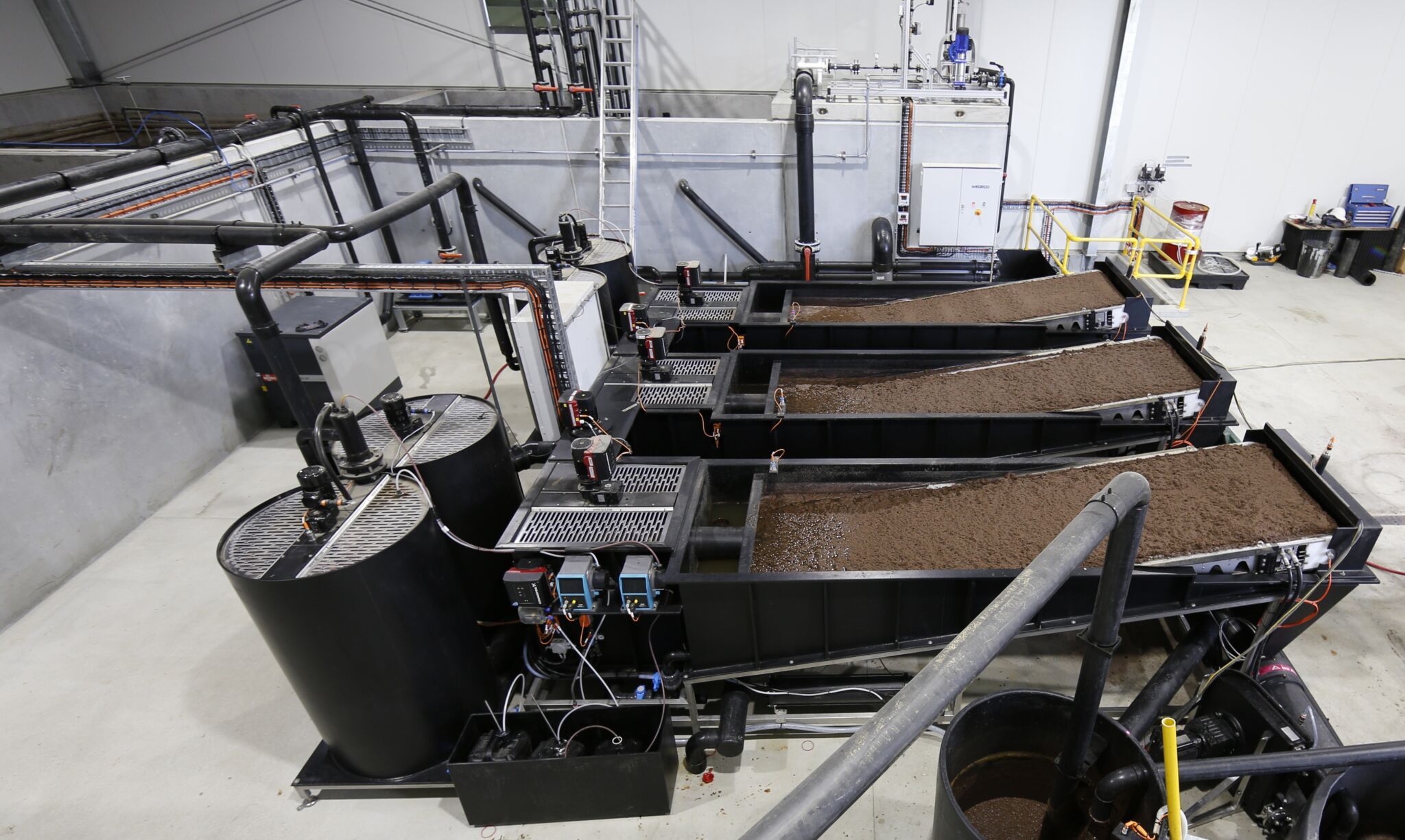

AL-2 Separation System installed in a purpose-built facility with operation and maintenance friendly environment

- Chemical-mechanical treatment of effluent

- Automatic operation and start-stop of the system

- Robust instrumentation and automation with online access

Effluent Treatment

Fish farm effluent is a combination of several streams which vary over the course of the day depending on cleaning of bio filters, increased faeces during feeding etc. The collective effluent has a high content of organics, fat and phosphorous which is not allowed to be discharged to the river.

AL-2 employs a three-stage coagulation process with separation on belt filters for the

The effluent is collected in a balance tank and equalised before treatment through an AL-2 Separation System. The treatment process is flow- and sensor-controlled chemical-mechanical treatment with separation on belt filters. The process captures SS, COD and phosphor, so the treated water can be discharged to the river and meet the consents.

The sludge removed by belt filters is further dewatered before being sold to a third party who mixes it with eucalyptus bark chip which is used as fertiliser in the local cherry tree orchards.