About carbon harvester

Efficient automated carbon removal

The present solution is primarily for municipal wastewater treatment plants or wastewater of a similar nature with a bigger volume to be treated. At conventional wastewater treatment plants, most of the organic matter is removed in biological processes. As an effective and environment-friendly alternative to primary clarifiers, the belt filter technology AL-2 Carbon Harvester can be used. Our solution for primary filtration can increase capacity on existing wastewater treatment plants with a limited space requirement or can be established as a primary step on new wastewater treatment plants.

Carbon harvester

Removal of organic matter

Average removal rates above 50% COD (above 75% particulate COD) and above 80% SS with a minimal polymer consumption. The carbon removal is optimized with automatic regulation of polymer dosing as a function of the wastewater load. After the belt filter technology, only dissolved solids and the smallest particles will remain. The belt filter technology leaves only the smallest particles and dissolved matters for the following biological treatment compared to a conventional wastewater treatment plant, where also large particles must be biologically decomposed. The solution gives a higher degree of removal under high loading, which evens out peak load and, in this way, gives a more even organic load in the following biological process.

At the wastewater treatment plants, it is important to maintain a reasonable COD/N ratio for the subsequent treatment. In case of excessive carbon removal, the operator can reduce the carbon removal by performing only mechanical filtration on the belt filters or bypassing. It makes it possible to control the subsequent biological process more freely.

Environmental benefits

Energy saving, biogas and microplastics

By choosing the AL-2 Carbon Harvester-solution, environmental benefits are achieved such as reduced energy for aeration, raw sludge for biogas and less sludge to dewater after the biological process. Besides the environmental benefits from the carbon harvester, AL-2 has documented retention of >99% microplastics in sludge fraction by this process. Thus, the solution can also contribute to reduce discharge of microplastics to the local water environment from the municipal wastewater treatment plants.

The process

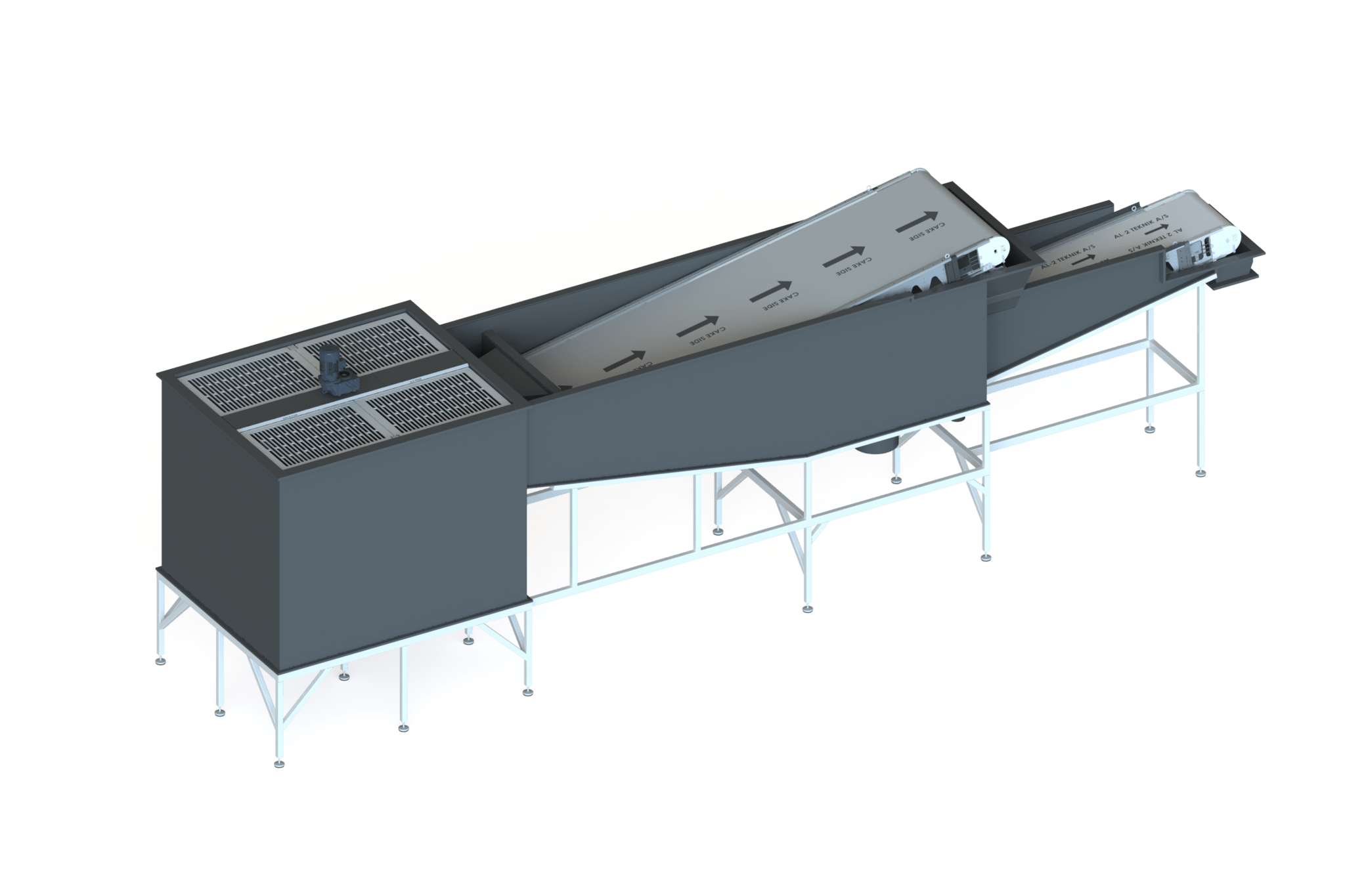

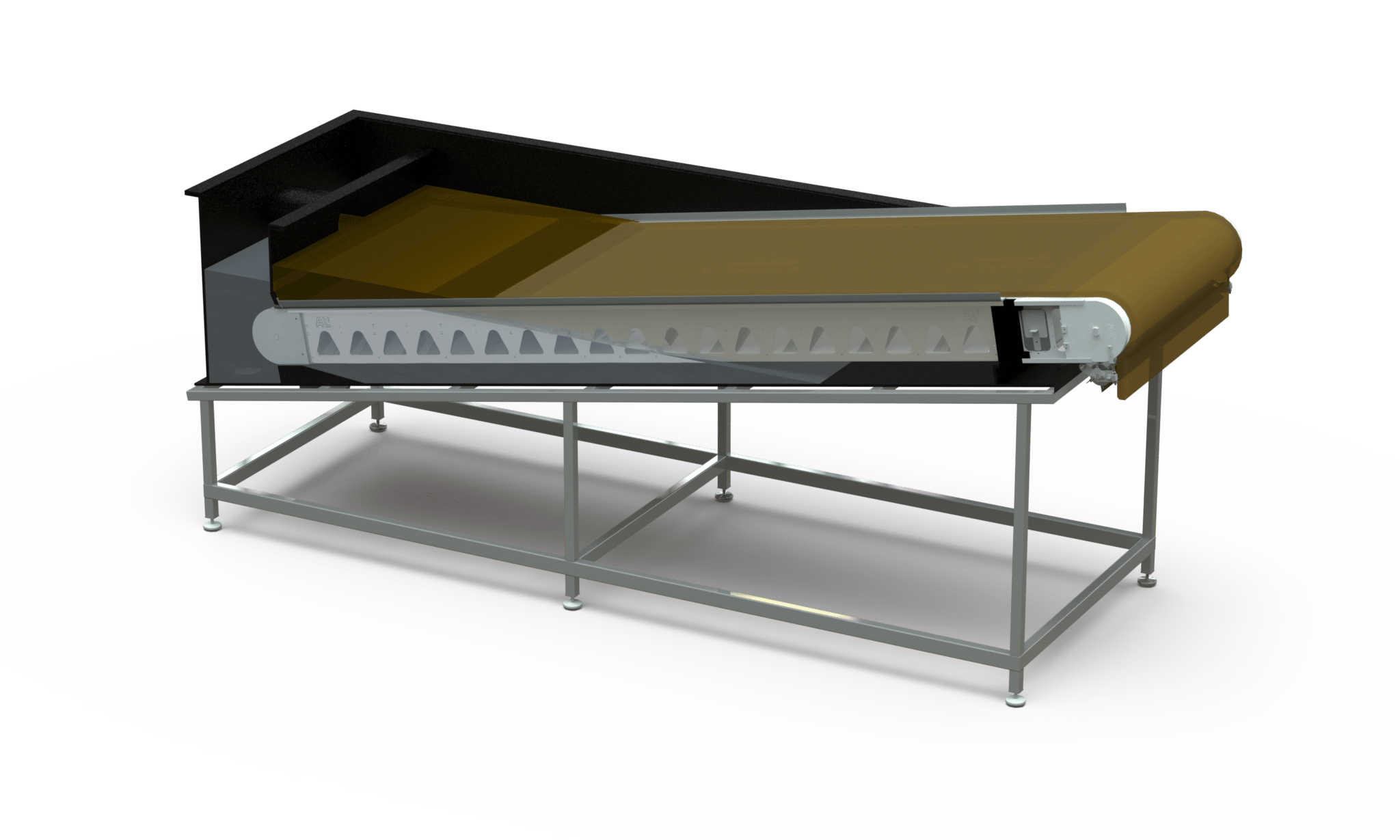

Advanced belt filter technology

A continuous flow of wastewater is pumped into the unit, where a precise and auto-adjusted polymer dissolution is added to create a flocculation process, where the particles are formed to larger flocks. The flocks are gently removed by the belt filter which separates particular sludge fraction from the waste water.

The sludge fraction after the belt filter is typically 4-8% dry matter, which is ideal for biogas. In cases where the sludge must be transported to a biogas facility nearby, a sludge dewatering belt filter can profitably be added. This option is integrated as a total part of the solution, and dewatering up to 20% dry matter without further addition of polymer are possible. This unique dewatering process leaves a low level of polymer in the sludge for the biogas plants.

The process is automated and regulated by flow- and sensor driven parameters with the option for external data communication.

Construction

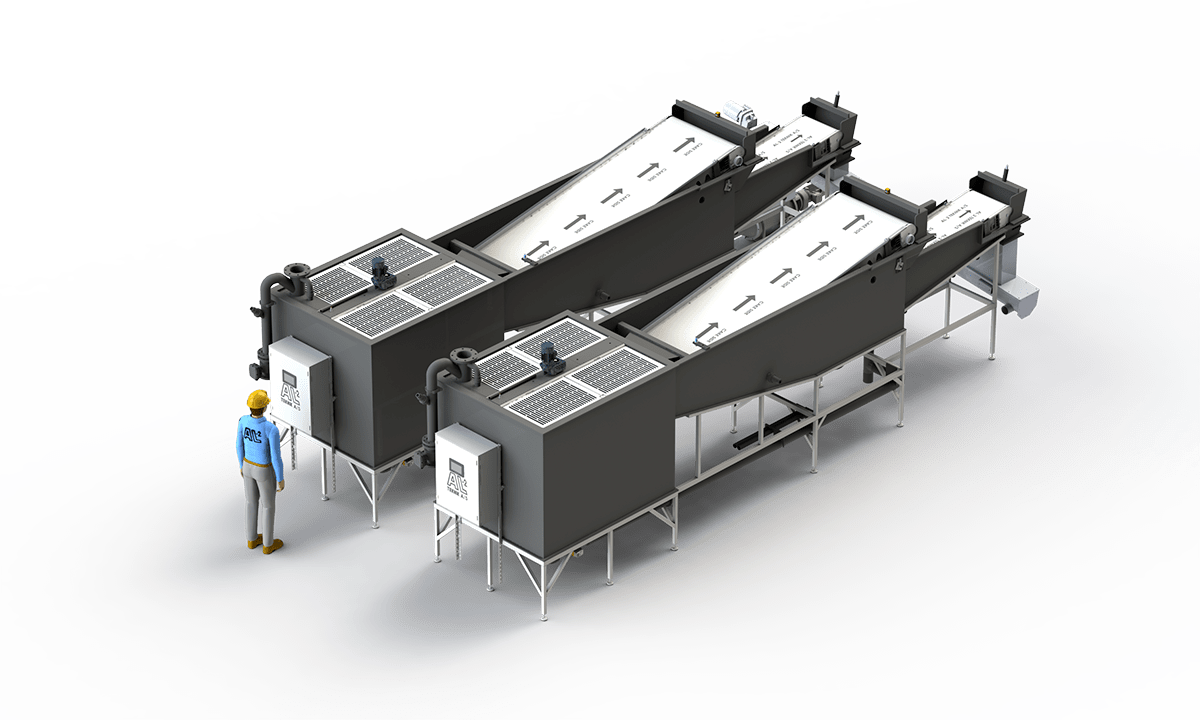

Capacity adapted to needs

AL-2 Carbon Harvester is manufactured in a standard module with a nominal flow capacity at 80 m3/hour. With larger volumes of water, the solution is constructed from several modules to achieve sufficient capacity. Modular construction offers many advantages, e.g. increased operational reliability and serviceability. The solutions are constructed in corrosion-resistant materials, primarily PE plastic and stainless steel (AISI304 or AISI316).

To ensure constant high quality, all our units are completed and thoroughly tested at our factory.

At the same time, this means that minimal installation work is required at the customer, which also makes our solutions attractive abroad, where strict wastewater treatment requirements bring the need efficient solutions.

Slam

Udløb

Spildevand / Flokkulering

3 of 6