About the unit

Automatic and reliable dosing

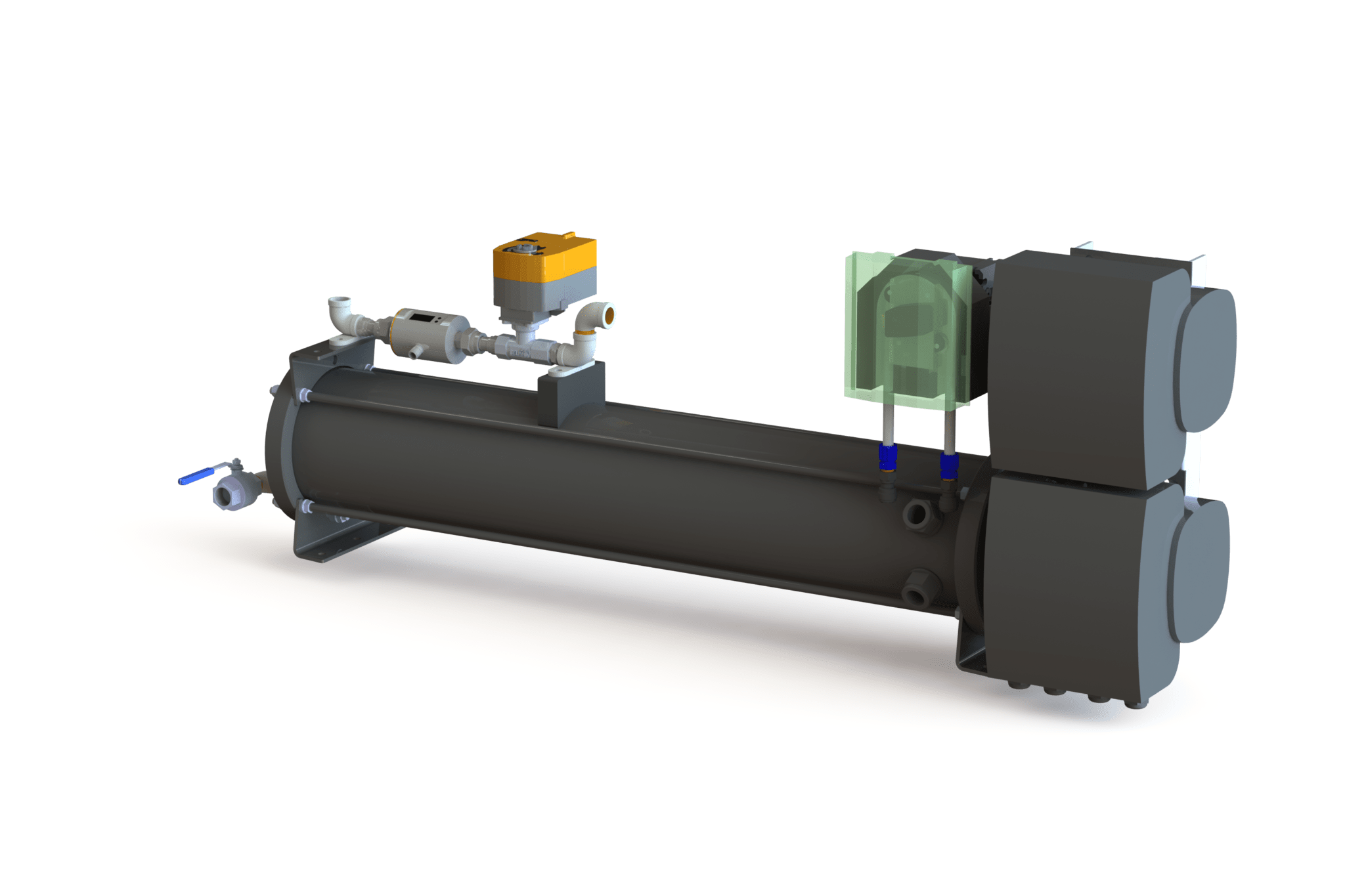

Polymer dosing unit for liquid polymer:

- Automatic dosing at water regulation, mixing, and maturation

- Accurate mixture with calibrated polymer dosing and automatic water regulation

- Reducing of costs on polymer use

- Make-up with technical water or mains water

Our polymer units are used in e.g.:

- AL-2 Separation System

- Primary treatment at municipal wastewater treatment plants

- Sludge treatment at municipal wastewater treatment plants

- Sludge treatment of industrial sludge

Capacity

Dosing capacity for two standard units

Amount of dosing for two standard units:

- Type 1: Water 200-1400 L/hour and polymer 12 L/hour

- Type 2: Water 200-3800 L/hour and polymer 12 L/hour

We also manufacture customized solutions, e.g. up to 6000 L/hour in water supply. With our industrial versions, which are part of the AL-2 Separation System, the water volume can often be regulated downwards to 40 L/hour. Flow monitoring for the polymer dosing are optional.

Operating

Automated with PLC-control

Most of our solutions are delivered with electrical control. PLC is used for calibration of dosing pump and for entering setpoints and readings of current process values. As standard, the units are equipped with an external start-stop signal, 4-20 mA input for amount of dosing and alarm relay. In addition, data communication is possible via Modbus TCP/IP.

Operational reliability

Avoid operational problems

The AL-2 Polymer System is often installed as a replacement of existing solutions to avoid operational problems. The robust mechanical construction and accurate dosing mean that significant savings can be achieved.

The solution has been developed over more than 20 years, where it has been a permanent part of AL-2 Separation Systems. In recent years, the system has been established as a stand-alone product that can be used in other contexts.